S45C Yakaoma Chrome Yakaputirwa Piston Tsvimbo YePneumatic Cylinders

Iyo pneumatic cylinder hydraulic piston tsvimbo inonziwo chrome-plated rod.Itsvimbo ine pamusoro inobatwa neakakosha kugaya uye yakaoma chrome plating.Inoshandiswa zvakanyanya mumasilinda akasiyana-siyana, hydraulic cylinders, kurongedza, kugadzira matanda, kuruka, kudhinda uye dhayi michina, kufa-casting zvikamu uye zvimwe otomatiki michina yekufambisa nekuda kwekuoma kwayo, iyo inogona kuwedzera hupenyu hwesevhisi yeyakajairwa chaiyo muchina nemidziyo.

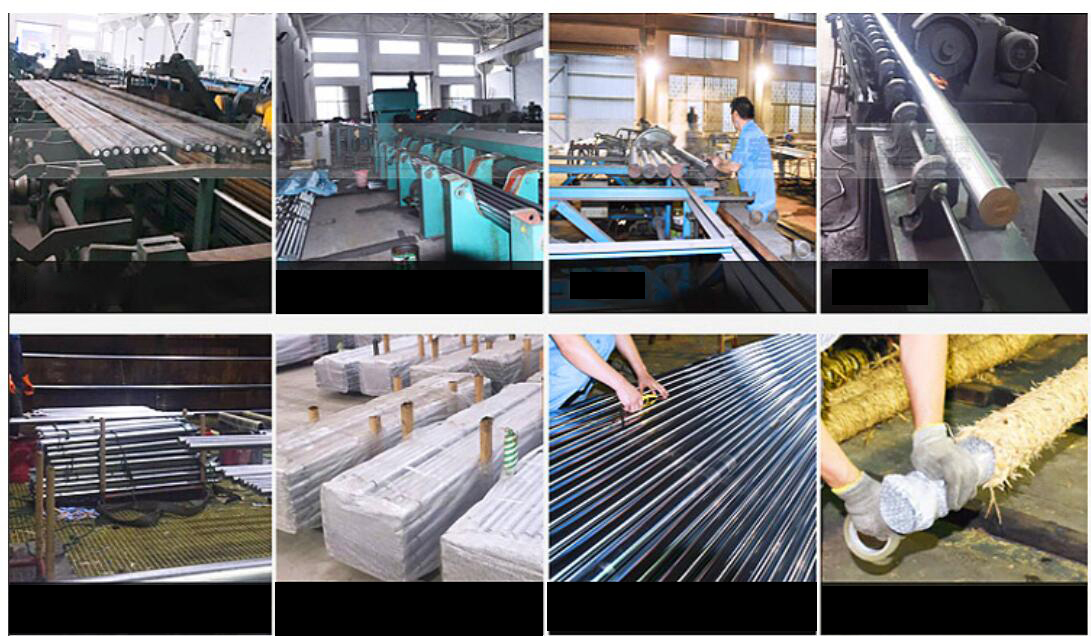

Isu takatora chaiyo inotonhora inodhonzwa, kukudza uye kupukuta kugadzira iyo pneumatic cylinder hydraulic piston tsvimbo, yega yega tekinoroji tarisiro inosangana neyakajairwa yenyika.

Detail Specification

zvinhu: CK45(GB/T699-1999)

Mechanical specification:

Kusimba kwesimba(Mpa):≥600N/mm2

0,2 Goho Kushungurudzika(Mpa):≥355N/mm2

Elongation:min.16%

Chrome Yakaiswa Hukobvu:φ<20mm≥15μm,kubvaφ20mm>20μm

Hushasha: Ra<0.2

Kuoma Chrome Layer:850HV-1050HV

Dhiyamita Kushivirira: f7,f8

Kururama: <0.1um/1000mm

Ovality:<1/2 dhayamita kushivirira

Kuongorora Corroseston Muedzo:ISO 10289:1999,IDT

Kunze dhayamita:3-120mm (GCr15) 3-40m(SUS440C)

Mamiriro ekutumira: Zvakajairika, Induction Harden, Q+T

Tafura yekugadzirwa kwemakemikari

| CHEMICAL COMPOSITION(%) | |||||||

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Diameter | Kurema | Kushivirira | Kushivirira | Kushivirira |

| mm | Kg/m | f7 (μm) | f8(μm) | h6(μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9.87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Chii chinonzi f7 uye f8 kushivirira zviyero:

Iyo yekushivirira huwandu hwef8 yakakura kupfuura iyo yef7, uye kuisirwa kunoenderana neinofananidzira gomba kushivirira zone level.Semuenzaniso, kana saizi yekutanga iri 10-18, f8(-0.016,-0.034), f7(-0.016,-0.027), kutsauka kwezvibvumirano zviviri zvakafanana, huwandu hwe f7 hudiki, uye kubvumidzwa. huwandu hwekuisa fit idiki.

Kuyerera Kwekugadzira

1 Danho: Peeling / Kutonhora Kudhirowa:

Cold kudhirowa inyanzvi yekugadzirisa tekinoroji yepneumatic cylinder piston tsvimbo.Kune pneumatic cylinder hard chrome plated rod, kutonhora kudhirowa kunoreva kudhirowa pasi pemamiriro ekunze tembiricha kuitira kuti uwane imwe chimiro uye mamwe ma mechanic properties.Zvichienzaniswa nekupisa kuumbwa, zvigadzirwa zvinotonhorwa zvinotonhora zvine zvakanakira kurongeka kwepamusoro uye kupera kuri nani kwepamusoro.

2 Danho: Kururamisa

Iyi nhanho tinogona kuve nechokwadi kuti yakaoma chrome yakapfatwa tsvimbo yakatwasuka zvakakwana.Izvo zvakakosha, kana uchiisa mukati meiyo pneumatic cylinder.Kutwasanuka kuri 0.2mm/m.

3 Danho: Kukudza

Honing processing inzira inoshanda yekugadzirisa iyo inogonesa iyo pneumatic cylinder piston rod pamusoro kuti iwane yakakwira chaiyo, yepamusoro yepamusoro uye hupenyu hurefu.Inogona kunyatso kuvandudza kurongeka kwedimensional, kurongeka kwechimiro uye kuderedza kukosha kweRa, asi haigone kuvandudza nzvimbo yegomba uye dzimwe nzvimbo.

4 Nhanho: Simbi yekupukuta

Kupukuta kunoreva kushandiswa kwemakanika, kemikari kana electrochemical mhedzisiro kuderedza kushata kwepamusoro kwepneumatic cylinder piston tsvimbo kuti uwane inopenya uye yakatsetseka.Iko kushandiswa kwezvishandiso zvekupukuta uye zvimedu zvinoputika kana imwe midhiya yekupukuta kugadzirisa pamusoro peiyo pneumatic cylinder piston tsvimbo.

5 Nhanho: Chrome Plating

Chrome plating inoreva chiitiko chekuisa chromium sejasi pane pneumatic hard chrome plated rod.

Iyo chromium-plated layer ine yakanyanya kuoma, uye kuoma kwayo kunogona kusiyanisa mukati mehupamhi hwakawanda hwe400-1200HV zvichienderana nekuumbwa kweiyo plating mhinduro uye maitiro ekugadzirisa.Iyo chrome-plated layer ine yakanaka yekudzivirira kupisa.Kana ichipisa pasi pe500 ℃, hapana shanduko iri pachena mukupenya nekuoma.Tembiricha inotanga kuita oxidize uye kuchinja ruvara kana tembiricha iri pamusoro pe500 ℃, uye kuoma kunodzikira kana kuri pamusoro pe700 ℃.Iko friction coefficient ye chrome layer idiki, kunyanya yakaoma friction coefficient, iyo yakaderera pakati pesimbi dzese.Naizvozvo, iyo chrome-plated layer ine yakanaka kupfeka kuramba.

Iyo chromium plating layer ine yakanaka kugadzikana kwemakemikari.Iyo haina mhedzisiro mualkali, sulfide, nitric acid uye yakawanda organic acids, asi inogona kunyungudika mu pneumatic acid (yakadai sepneumatic acid) uye inopisa sulfuric acid.Muchikamu chechiedza chinooneka, kuratidza kwechromium kunenge 65%, iri pakati pesirivha (88%) uye nickel (55%).Nekuti chromium haichinji ruvara, inogona kuchengetedza kutaridzika kwayo kwenguva yakareba uye iri nani pane sirivheri uye nickel.

6 Nhanho: Chrome yakaputirwa tsvimbo Kupenya mushure mekuputirwa

Electroplating uye polishing: inzira mbiri dzakasiyana dzekurapa pamusoro pesimbi uye zvimwe zvinhu.Iyo yekutanga kurapwa kwemakemikari, uye iyo yekupedzisira ndeye mechanical treatment.

Electroplating: Maitiro ekushandisa electrolysis kubatanidza chidimbu chesimbi firimu pamusoro pesimbi kana zvimwe zvinhu.Inogona kudzivirira ngura, kunatsiridza kupfeka kuramba, magetsi conductivity, reflectivity uye kuwedzera aesthetics.

Kupolisha: Shandisa maturusi ekupurudzira anochinjika uye zvimedu zvinoputika kana imwe midhiya yekupuruzira kugadzirisa pamusoro peiyo workpiece.Kupenya hakugone kuvandudza kurongeka kwedimensional kana geometric iko kweiyo workpiece, asi ine chinangwa chekuwana yakatsetseka pamusoro kana girazi gloss.

7 Nhanho: Chrome yakaputirwa tsvimbo Yekuyedzwa Kwemhando

Piston tsvimbo dzakaitwa electroplating uye polishing maitiro anowanzo kuperekedzwa nekuremara kwekuputira senge chrome makomba uye gomba.Hukuru uye huwandu hwezvirema izvi zvinokanganisa zvakananga kuita kwepiston tsvimbo.Kudzikisa kukanganisa kwehurema uhwu papiston tsvimbo, kune rumwe rutivi, nekuvandudza mhando yezvigadzirwa, kuvandudza tekinoroji yekugadzira, uye kuderedza kuitika kwehurema;kune rumwe rutivi, zvinodikanwa kunyatsoona zvikanganiso zveplating mushure mekuita kwekupukuta kudzivirira zvigadzirwa zvisina kukodzera kubva mufekitori.Mainjiniya eAutoair vanoona otomatiki kukanganisa nerubatsiro rweruzivo rwesainzi yemifananidzo

8 Danho: Kurongedza

FAQ:

Q1: Chii chinonzi pneumatic cylinder piston tsvimbo?

A: Iyo piston tsvimbo chinhu chakakosha uye chakakosha chikamu cheese hydraulic kana pneumatic cylinder.Iyo piston tsvimbo kazhinji ndeyekureba kwakamisikidzwa kweyakaoma chrome yakanamirwa inotonhora yakapera simbi bhaa iyo inoendesa simba rakagadzirwa nepiston kuchikamu chemuchina chiri kuita basa.

Q2: Ndeipi musimboti wepneumatic cylinder piston tsvimbo?

A: Iyo pneumatic cylinder piston iri mucylinder inotakura kupinza kana kudhonza simba rinogadzirwa nemhepo, uye yakananga inoshanda pane pneumatic cylinder piston tsvimbo yakabatana nepiston, uye ipapo pneumatic cylinder piston tsvimbo inobatanidzwa kune inotakura workpiece kufamba. shure uye mberi.

Q3: Chii chinonzi mbishi chepneumatic cylinder piston tsvimbo yako

A: Kazhinji, iyo pneumatic cylinder piston tsvimbo yepneumatic cylinder ichasarudza 45# simbi seyakagadzirwa.Kana iyo silinda inogadzirwa ichida kushandiswa munzvimbo yakakosha, 304 simbi isina tsvina inogona zvakare kushandiswa

Q4: Sei uchisarudza 45 # simbi seyakagadzirwa zvinhu

A: 45# simbi ndeyepamusoro-mhando kabhoni structural simbi ine yakaderera kuoma uye nyore kucheka.Mushure mekudzima, kuoma kwayo kwepamusoro kunogona kusvika 45-52HRC.Uye inogona zvakare kuve nekuita zvirinani kucheka uye kusimba kwepamusoro, kuomarara uye mamwe akakwana emuchina zvivakwa, saka ndechimwe chezvinhu zvinowanzo shandiswa zveshaft zvikamu.

Q5: Ndeipi machining maitiro eiyo pneumatic cylinder piston tsvimbo?

A: Kuti uwane yakagadzikana machining quality, manual straightening yepiston tsvimbo haibvumirwi mushure mokunge machining atanga.Naizvozvo, nzira yekururamisa inofanira kuitwa pamberi pekugadzira.Nekuda kwekusaomarara kusimba kweiyo workpiece, kutendeuka kwakashata uye kutendeuka kwakanaka kunofanirwa kuitwa panguva yekugadzira machining kuvandudza machining kurongeka.Iyo yekushanda yepiston tsvimbo iri kudzoreredza mutsara kufamba.Kuti uvandudze hupenyu hwesevhisi yepiston tsvimbo, kumusoro kunofanirwa kuve chrome-yakaputirwa kuti ivandudze kuoma kwayo kwepamusoro uye kupfeka kuramba.Mushure me chrome plating, kurapwa kwekukwenenzverwa kunodiwa kuti uwane hutsinye hwepamusoro, kuderedza friction factor, uye kugadzirisa chisimbiso kuita.Sezvo kukwenenzverwa kunenge kusingaite padhayamita yekunze yepiston tsvimbo, iyo workpiece inoda kuwana yakakwira pamusoro roughness pamberi pe chrome plating.Naizvozvo, zvinodikanwa kuti uwedzere nzira yakanaka yekukuya pamberi peiyo chrome plating process (kunyatso kugaya kunogona zvakare kunatsiridza kunamatira kwepamusoro kwechromium. ).Zvichienderana nekuongorora kuri pamusoro, iwo anonzwisisika maitiro ekugadzirisa episton tsvimbo ndeaya: kutwasanudza-rough kutendeuka-yakanaka kutendeuka-yakanaka kugaya-chrome plating-kupolisha.

Q6: Chii kupenya kwepneumatic cylinder piston tsvimbo

A: Munguva yekutendeuka, gomba repakati rinoita basa rekuisa rinoratidza imwe dhigirii yekupfeka.Kuti ive nechokwadi chekubatana kwemabenchmarks, gomba repakati rinofanirwa kuchekwa risati rakuya kuti ive nechokwadi chekugadzirisa kunaka.Paunenge uchikuya, kuedza kukuya kunofanira kuitwa kune denderedzwa rekunze pedyo nekuguma kwekutanga, uye kukuya kwepiston tsvimbo inogona kuitwa chete kana mamiriro ekumhanya achisangana nezvinodiwa zvekugadzirisa.Pamusoro pekuvandudza kurongeka kwedimensional, iyo yakanaka yekukuya maitiro inodawo kuwana yakakwirira pamusoro roughness pane yakashongedzwa pamusoro kuti ivandudze hukama hwechromium ions panguva ye electroplating process.Kuti ive nechokwadi chekuti ukobvu hwechromium plating layer yepiston rod yekupedzisira yakafanana, kushata kwepamusoro mushure mekukuya kunofanirwa kunge kuri pedyo nekushata kwepamusoro mushure mekugadzirwa kwechromium uye kupenya.Kana hutsinye hwepamusoro hwepiston tsvimbo inodiwa kuti ive yakakwirira, yakadai seRa <0.2 μm, inofanira kunge yakatsetseka.Wedzera super fine grinding kana polishing process mushure mekukuya.