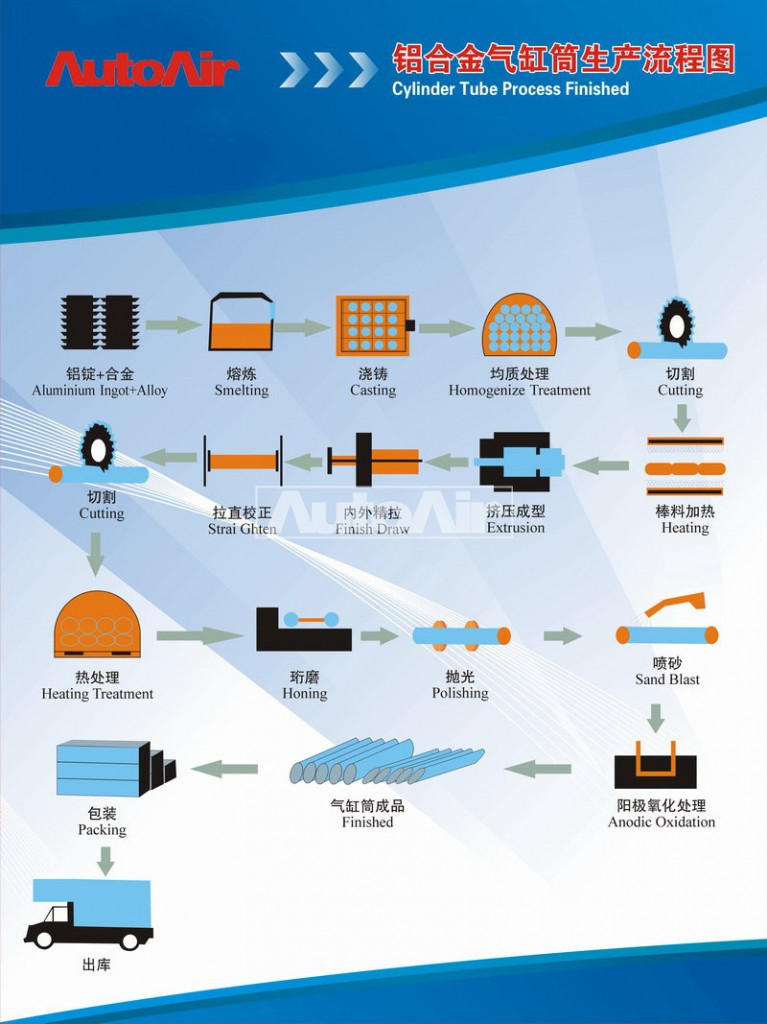

Iyo Yekugadzira Maitiro ePneumatic Cylinder Tube

Raw Material workshop

Raw Material workshop

Extrusion Workshop

Extrusion Workshop

Pedzisa Draw workshop

Pedzisa Draw workshop

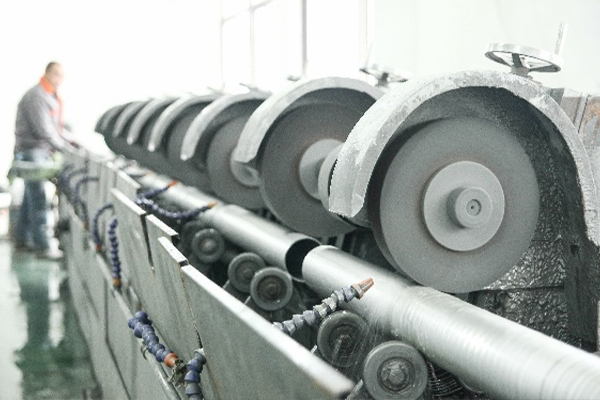

Honing Workshop

Honing Workshop

Polishing Workshop

Polishing Workshop

Sand Blast Workshop

Sand Blast Workshop

Anodic Oxidation Workshop

Anodic Oxidation Workshop

Kurongedza Pneumatic cylinder Tube

Kurongedza Pneumatic cylinder Tube

Ready material workshop

Ready material workshop

Chekutanga pane zvese, mushure mekugamuchira mutengi akadhirowa akadhirowa kana mutengi atora yedu yakajairwa mifananidzo, isu tichatenga mbishi zvinhu zvekuvhura mold.

Danho 1:Yakawedzera Aluminium mbiri senge kudhirowa ne mold

2 seti yeheavy-duty aluminium profile extrusion michina

Danho rechipiri:Pedzisa kudhirowa

Danho rechitatu:Nyora

Danho 4:Kucheka

Danho rechishanu:Kupisa kurapwa

Danho rechitanhatu:Honing

12 seti yePneumatic silinda chubhu honing michina

FAQ:

Q1: Chii chinonzi honing?

A: Kupedzisa kugadziriswa kwepamusoro pekupedzisa newhetstone (inonziwo honing stick) yakasungirirwa mumusoro wehoning.Iyo inozivikanwawo seinofinha.Iyo inonyanya kugadzirisa maburi akasiyana-siyana ane dhayamita ye5 kusvika 500 mm kana kutokura, uye chiyero chegomba rakadzika kusvika padhayamita yegomba inogona kusvika gumi kana kupfuura.Mune mamwe mamiriro ezvinhu, inogona zvakare kugadzira ndege, kunze kwedenderedzwa, nzvimbo dzakatenderera, mazino, nezvimwe. Iyo yekunze denderedzwa yemusoro wehoning yakashongedzwa ne 2-10 whetstones nehurefu hunosvika 1/3 kusvika 3/4 ye gomba kureba.Pakurikudza gomba, inotenderera ichidzokera kumashure.Panguva imwecheteyo, inowedzera zvakaenzana nechitubu kana hydraulic control mumusoro wehoning.Nokudaro, nzvimbo yekubatana nepamusoro pegomba yakakura, uye kushanda kwekugadzirisa kwakakwirira.Kurongeka kwakaringana kwegomba mushure mekukudza iIT7 ~ 4, uye kushata kwepamusoro kunogona kusvika kuRa0.32 ~ 0.04 microns.Saizi yemvumo yehoning inoenderana negomba dhayamita uye zvinhu zvechishandiso, kazhinji 0.02 ~ 0.15 mm yezvikamu zvesimbi yakakandwa uye 0.01 ~ 0.05 mm yezvikamu zvesimbi.Kutenderera kunotenderera kwemusoro wehoning kunowanzo 100 ~ 200 rpm, uye kukurumidza kwekufamba kwekudzoka kunowanzova 15 ~ 20 m / min.Kuti ubvise machipisi ekucheka uye zvimedu zvinoputika, kuvandudza kushata kwepamusoro uye kuderedza tembiricha yenzvimbo yekucheka, yakawanda yekucheka mvura, senge parafini kana shoma shoma yemafuta eku spindle, inowanzoshandiswa panguva yekushanda, uye dzimwe nguva yakanyanya kudzvinyirira emulsion inoshandiswawo.

Danho rechinomwe:Kupukuta

2 seti yemichina yekupukuta pamusoro

Nhanho 8:Kuputika kwejecha

2 seti dzepamusoro sandblasting michina

FAQ

Q1: Chii chinonzi jecha kuputika?

A: Maitiro ekushandisa kukanganisa kwejecha rinomhanya-mhanya kuchenesa uye roughen pamusoro pe substrate.Mhepo yakamanikidzwa inoshandiswa sesimba kugadzira danda rejet rinomhanya kwazvo kupfapfaidza zvinhu (copper ore, jecha requartz, emery jecha, jecha resimbi, jet reHainan) nekumhanya kusvika pamusoro pechishandiso chinorapwa, kuitira kuti. chitarisiko kana chimiro chekunze kweiyo workpiece surface inoshandurwa , Nekuda kwekukanganisa uye kucheka chiito cheabrasive pamusoro peiyo workpiece, pamusoro peiyo workpiece inogona kuwana imwe dhigirii yehutsanana uye roughness yakasiyana, kuitira kuti. iyo mechanical properties ye workpiece surface inovandudzwa, nokudaro kuvandudza kuneta kuramba kweworkpiece, uye kuwedzera kwayo uye kuvhara Kusungirirwa pakati pezvikamu kunowedzera kusimba kwefirimu yekuputira, uye kunobatsirawo kuenzana nekushongedza kwekuputira.

Nhanho 9:Anodizing

2 seti yeanodizing mitsetse yekurapa

FAQ:

Q1: Chii chinonzi anodizing?

A: Anodic oxidation, iyo electrochemical oxidation yesimbi kana alloys.Aluminium uye alloys ayo anoumba layer ye oxide firimu pane aruminiyamu zvigadzirwa (anode) pasi pechiito chekushandiswa ikozvino pasi pe electrolyte inoenderana uye chaiyo process mamiriro.Kana anodizing isina kutaurwa, inowanzoreva sulfuric acid anodizing.

Kuti ukunde hurema hwealuminium alloy pamusoro kuoma, kupfeka kuramba uye zvimwe zvinhu, kuwedzera chiyero chekushandisa, uye kuwedzera hupenyu hwesevhisi, tekinoroji yekurapwa kwepamusoro yave chikamu chakakosha chekushandiswa kwealuminium alloy, uye tekinoroji yeanodizing parizvino. inonyanya kushandiswa uye yakabudirira zvikuru ye.

Nhanho 10:Yakapera aluminium silinda machubhu

Nhanho 11:Aluminium silinda machubhu kurongedza