TCM-A/TCM-B SERIES GUIDE ROD CHINA ALUMINIUM ALLOY TUBE

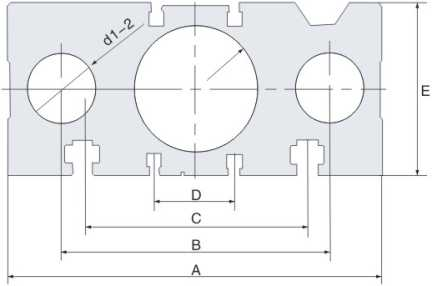

TCM-A (φ12-80) Series Cylinder Tube

| No | d | d1-2 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ12.5 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ14.5 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27.5 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27.5 | 162 | 124 | 110 | 34 | 78 |

| g | φ80 | φ34 | 202 | 156 | 140 | 48 | 91.5 |

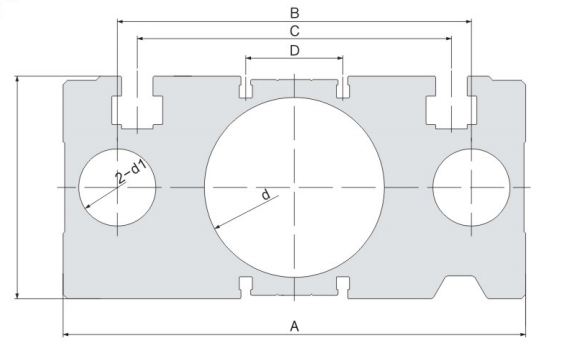

TCM-B (φ12-63) Series Cylinder Tube

| NO | d | 2-d1 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ13 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ17 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27 | 162 | 124 | 110 | 34 | 78 |

Material of Aluminium Alloy Profile Aluminium pneumatic cylinder chubhu: aluminium alloy 6063 T5

Yedu yakajairwa Kureba ndeye 2000mm, kana ichida humwe hurefu, ndapota wakasununguka kutizivisa.

Anodized pamusoro: Inner chubhu-15±5μm Outer chubhu-10±5μm

Zvibvumirano zvekugadzira FESTO, SMC, Airtac, Chelic nezvimwe.

Zvibvumirano kune yakajairwa ISO 6430 ISO6431 VDMA 24562 ISO15552 nezvimwe.

Inoshandiswa kune yakajairika cylinder, compact cylinder, mini cylinder, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper etc. Zvakare kune mamwe masilinda akakosha.

Kemikari Kuumbwa:

| Kuumbwa Kwemakemikari | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Tsanangudzo:

| Kusimba Kwesimba (N/mm2) | Kusimba Kwegoho (N/mm2) | Ductility (%) | Pamusoro Kuoma | Internal Diameter Kururama | Mukati Hukasha | Kutwasuka | Makobvu Error |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Kushivirira kweAluminium Alloy Tube:

| KUTUNGAMIRIRA KWEALUMINIUM ALLOY TUBE | ||||||

| Bore Size | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: Chii chinonzi TCM modhi?

A: Chigadzirwa chimiro

1. JIS mwero unoitwa

2. Nhungamiro mbiri dzesimbi yakakosha uye mutsara wekutakura kana bhuronzi inotakura girairi inoshandiswa kudzivirira kutenderera.Vanogona kutakura torque yakakwirira uye radial mutoro.

3. Dhiraivha chikwata uye chikwata chekutungamira chiri mubhodhoro rimwe chete kuti hapana zvimwe zvekuwedzera zvinodiwa nenzvimbo shoma inodiwa Kupinda kwemhepo kunosarudzwa uye zviri nyore kuisa.

4. Pasi, rutivi rwekumashure uye chigadziko chekugadzirisa chemuviri mukuru zvichienderana nemaitiro maviri chaiwo ekutarisa (Ona PA orifice uye orifice mu XX point), iyo inogona kupa kugadzika kwekugadzirisa nepamusoro-soro yemamiriro ezvinhu anokosha.

5. Sarudzo dzekuchinja kukwira nekupa 4 inokwira slots.

6. Yakakosha dhizaini yemuviri mukuru inopa akawanda-gomo;

Q2: Kana tikatenga TCM, zvinoita here neanodizing yeAluminium Air Cylinder Tubes?

A: Iyi Pneumatic Cylinder haikurudzirwe kuve neoxidized, nekuti mutengi anoda kuicheka ega obva aigadzira uye ozoita kurapwa kweokisijeni mushure mekuitenga.

Q3: Ndeupi hurefu kana tikaraira Pneumatic Cylinder Tube Pipe?

A:Kureba i2 metres.

Q4: Whatinguva yekutumiranezve Aluminium Profile YeMhepo Cylinder?

A: ☆ Kana machubhu akagadziridzwa, nguva inoda 50-60 mazuva ekushanda, asi kana kune akajairwa machubhu, yedu yekuendesa nguva ndeye 15-20 mazuva ekushanda.